- Marketplace

- Merchants

- Restaurants

- UAE house

- Cloud accounting (GCC VAT)

- Me

- Cart

- My order

- Address book

- Favorite

- Link

- About us

- Download App

- 中文

- Merchant panel

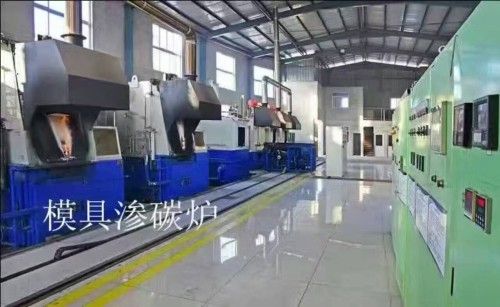

Tianjin Jianfeng mold manufacturers are fully automated vacuum carburizing heat treatment

Fully automatic vacuum heat treatment carburizing furnace before the room, after the room, carburizing time required 730 minutes, the specific steps are:

1, into the furnace before the room ventilation 10 minutes, does not allow the air to maintain a vacuum state

2, into the room after heating to 930 degrees, soaking heat for 20 minutes

3, propane carbon potential (carbon content) rose to 1.2, the temperature 930 degrees to maintain 420 minutes

4, carbon potential down to 0.85, the temperature 930 degrees to maintain an hour

5, cooling to 860 degrees to maintain 20 minutes, carbon potential 0.85

6, baked to the front chamber quenching (oil cooling, rapid cooling process heat treatment process) 20 minutes

7, oil control for 30 minutes

8, 200-220 degrees Tempering (quenching of the workpiece should be tempered in time to reduce its hardness and strength to improve its ductility or toughness) 150 minutes

Above is fully automatic vacuum carburizing furnace carburizing process, the hardness of the mold remained at 57 ° -62 °, so customers do not say our friends die too long product cycle, the so-called slow work fine work, Especially in Jianfeng company all procedures are digital management of the state to give you a satisfactory product, and so it is worth it 'happy' Order Phone 15122965266 Zhang Research